Enter your text here...

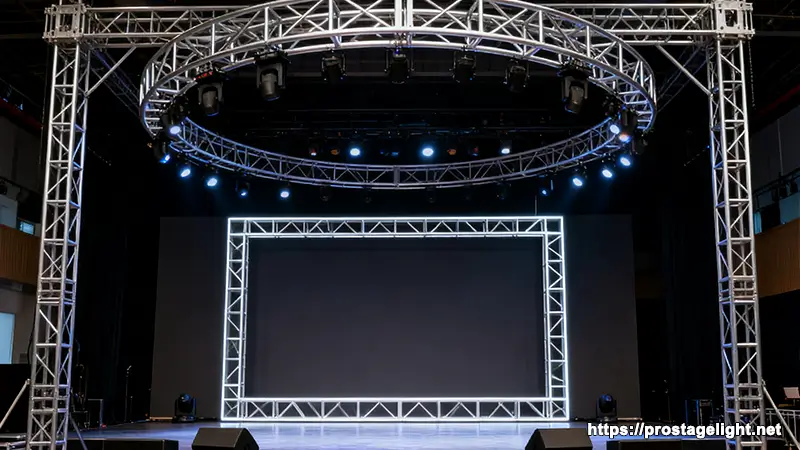

Premium Stage Truss & Lighting Solutions

– Built for Your Success!

What is a Lighting Truss?

Lighting truss or stage lighting truss is a structural framework used to support and position lighting equipment, such as stage lights, or other fixtures, in various settings like concerts, theaters, events, and film productions; It is typically made of aluminum or steel.

Common Types of Lighting Trusses:

Square Trusses are categorized by their connection method: Spigot-type and Screw-type.

What are the differences between Spigot-type and Screw-type square trusses?

Spigot-type Square Truss

Design and Connection:

- Spigot Connection: This type of truss uses a spigot (a pin or peg) to connect the sections. The spigot fits into a corresponding socket, creating a secure joint.

- Ease of Assembly: Spigot-type trusses are generally quicker to assemble because the spigot and socket system is straightforward. You just slide the spigot into the socket, and you're good to go.

- Stability: Once connected, the spigot system provides a stable and rigid structure, which is crucial for heavy loads or long spans.

Common Uses:

- Temporary Structures: Often used in stages, event rigging, and temporary installations where quick assembly and disassembly are needed.

- Light to Medium Loads: Suitable for applications that don't require extreme weight-bearing capacity.

Screw-type Square Truss

Design and Connection:

- Screw Connection: This type uses screws or bolts to secure the truss sections together. The screws are tightened to ensure a firm connection.

- Adjustability: Screw-type trusses offer more adjustability. You can fine-tune the tightness of the connection, which can be useful in certain setups.

- Strength and Durability: The screw connections provide a very strong and durable joint, making this type of truss suitable for heavier loads and more permanent installations.

Common Uses:

- Permanent Installations: Often used in permanent structures like building frameworks, bridges, and other applications where long-term stability is crucial.

- Heavy Loads: Ideal for situations where the truss needs to support significant weight, such as in industrial settings or large-scale event rigging.

Key Differences Spigot-type Square and Screw-type Square Truss

1. Connection Method:

- Spigot-type: Uses a spigot and socket system.

- Screw-type: Uses screws or bolts for connection.

2. Assembly Speed:

- Spigot-type: Faster to assemble due to the simplicity of the spigot system.

- Screw-type: Takes longer because each screw needs to be tightened.

3. Adjustability:

- Spigot-type: Less adjustable once connected.

- Screw-type: More adjustable, allowing for fine-tuning.

4. Load Capacity:

- Spigot-type: Suitable for light to medium loads.

- Screw-type: Better for heavy loads and more demanding applications.

5. Common Applications:

- Spigot-type: Temporary structures, stages, event rigging.

- Screw-type: Permanent installations, heavy-duty applications.

In summary, if you're looking for something quick and easy to set up for a temporary event, go with the Spigot-type Square Truss. But if you need something robust and adjustable for a more permanent or heavy-duty application, the Screw-type Square Truss is your best bet. Both have their place in the industry, and choosing the right one depends on your specific needs.

Truss types with different appearances

| Truss Type | Key Characteristics | Best For | Visual Appeal |

|---|---|---|---|

| Ladder Truss | Lightweight, simple (two parallel chords), easy to transport. | Basic lighting setups, small stages, trade show booths, where budget and portability are key. | Simple, functional, less prominent. |

| Triangular Truss | Stronger than ladder truss, versatile, three chords add stability. | Medium-duty applications, hanging speakers, lighting, and decorative elements. More stable for overhead use. | More visually interesting than ladder truss, often used for its geometric profile. |

| Box Truss | Highest load capacity, very rigid, square or rectangular shape. | Heavy loads like large video walls, complex lighting rigs, and motors for large stages and concerts. | Substantial and industrial; the standard for major productions. |

| Arch Truss | Curved design, combines high strength with a dynamic shape. | Creating entranceways, stages with curved tops, and structures where the truss itself is a design feature. | High visual impact. Creates a more elegant and flowing look than angular trusses. |

| Custom Truss | Tailored to specific needs, unique shapes and sizes. | Unusual stage layouts, specific branding integration, or supporting one-of-a-kind equipment. | Unique and tailored to the event's creative vision. |

Besides the basic type, several factors influence the choice of stage truss:

Material: Aluminum is most widely used due to its light weight and strength. Steel is suitable for heavy-duty, permanent applications and has a limited scope of use.

Load Capacity: The most critical specification. Understand point loads (single point weight) and UDL (uniformly distributed weight).

Span: The maximum unsupported distance. Box trusses generally span farther than ladder trusses.

Connectors: Quick-pins for speed, bolts for maximum strength. They ensure safety and setup affect time.

How much weight can stage lighting truss hold?

The weight capacity of a lighting truss depends on several factors: the type of truss (ladder truss, triangular truss, square truss, etc.), the material used (typically high-grade aluminum alloys like 6061-T6 or 6082-T6), and the design and installation method. The most common types are steel truss and aluminum truss. Additionally, load distribution—whether the load is evenly distributed or concentrated—plays a significant role.

Steel trusses can withstand slightly heavier weights, but due to their own weight and processing challenges, aluminum trusses are more prevalent in the stage lighting industry. Aluminum trusses are lightweight yet strong enough to carry heavy equipment.

Srew-type Square Truss:

Aluminum truss with dimensions of 300×300mm:

- Dimensions (W×H): 300×300mm

- Main Tube: Φ50×3mm

- Vice Tube: Φ30×2mm

- Brace: Φ25×2mm

Weight-Bearing Capacity (Distributed Load):

| Length (ft/m) | Distributed Load (kg/lb) |

|---|---|

| 19.68504ft (6m) | 337742.95 kg/lb |

| 26.24672ft (8m) | 245540.13 kg/lb |

| 29.527ft (9m) | 190418.87 kg/lb |

| 32.8084ft (10m) | 150930.69 kg/lb |

| 39.37008ft (12m) | 100220.46 kg/lb |

Aluminum truss with dimensions of 500×500mm:

- Dimensions (W×H): 500×500mm

- Main Tube: Φ50×3mm

- Vice Tube: Φ50×2mm

- Brace: Φ25×2mm

Weight-Bearing Capacity (Distributed Load):

| Length (ft/m) | Distributed Load (kg/lb) |

|---|---|

| 39.37008ft (12m) | 1100 kg / 2425.08 lb |

| 45.9317585ft (14m) | 1050 kg / 2314.85 lb |

| 52.4934383ft (16m) | 1000 kg / 2204.62 lb |

| 59.0551181ft (18m) | 800 kg / 1763.69 lb |

| 65.6167979ft (20m) | 900 kg / 1984.16 lb |

Length vs. Load Capacity: As the length of the truss increases, the distributed load capacity decreases. This is typical for trusses, as longer spans are subject to greater bending forces.

Material and Design: The truss is made of aluminum with specific tube dimensions, which contribute to its strength and weight-bearing capacity.

Practical Considerations

Safety Factor: Always apply a safety factor (e.g., 2:1 or 3:1) to the load capacity to ensure the truss is not overloaded.

Installation: Proper installation and support points are critical to achieving the stated load capacity.

Load Distribution: Ensure the load is evenly distributed to avoid exceeding the truss's capacity at any point.

Spigot-type Square Truss:

Aluminum truss with dimensions of 290×290mm:

- Dimensions (W×H): 290×290mm

- Main Tube: Φ50×3mm

- Vice Tube: None (the four sides are sloped tubes)

- Brace: Φ20×2mm

Weight-Bearing Capacity (Distributed Load):

| Length (ft/m) | Distributed Load (kg/lb) |

|---|---|

| 19.68504ft (6m) | 1200 kg / 2645.54 lb |

| 26.24672ft (8m) | 900 kg / 1984.16 lb |

| 32.8084ft (10m) | 700 kg / 1543.23 lb |

| 39.37008ft (12m) | 600 kg / 1322.77 lb |

| 45.9317585ft (14m) | 500 kg / 1102.31 lb |

Aluminum truss with dimensions of 520×520mm

- Dimensions (W×H): 520×520mm

- Main Tube: Φ50×3mm

- Vice Tube: Φ50×2mm

- Brace: Φ25×2mm

Weight-Bearing Capacity (Distributed Load):

| Length (ft/m) | Distributed Load (kg/lb) |

|---|---|

| 39.37ft (12m) | 1400 kg / 3086.47 lb |

| 45.931ft (14m) | 1250 kg / 2755.77 lb |

| 52.49ft (16m) | 1000 kg / 2204.62 lb |

| 59.055ft (18m) | 900 kg / 1984.16 lb |

| 65.61ft (20m) | 800 kg / 1763.69 lb |